Roadmap ERP's Planning and Manufacturing:Discover News Avenues

01

Bill of Material

Appraise your stock, gear, and money, against the factors to fix the produce; concoct fool-proof planning and workflow linking; achieve efficient fabrication; and deliver produce uncompromised by time and quality.

02

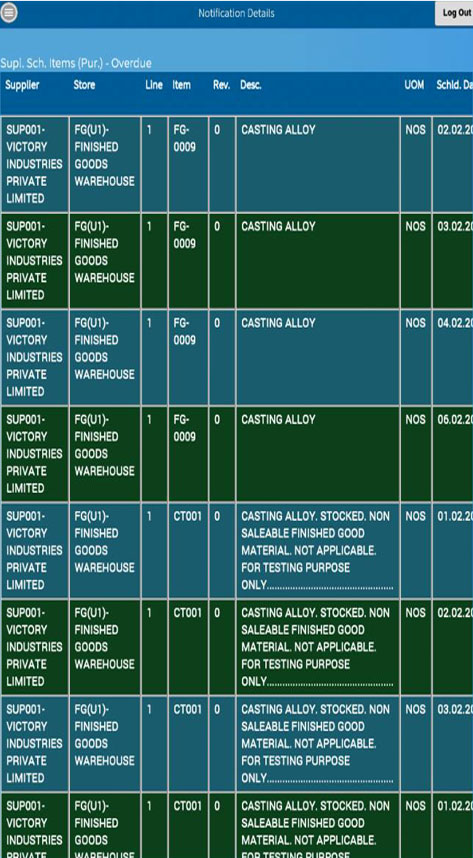

Material Requirement Planning (MRP)

Rein in costs via efficient Inventory control, ability to assess effects of Changes to Cost; procure and produce in accord with Demand Vs Supply reports; and aptly feed the process to ensure seamless on-time production.

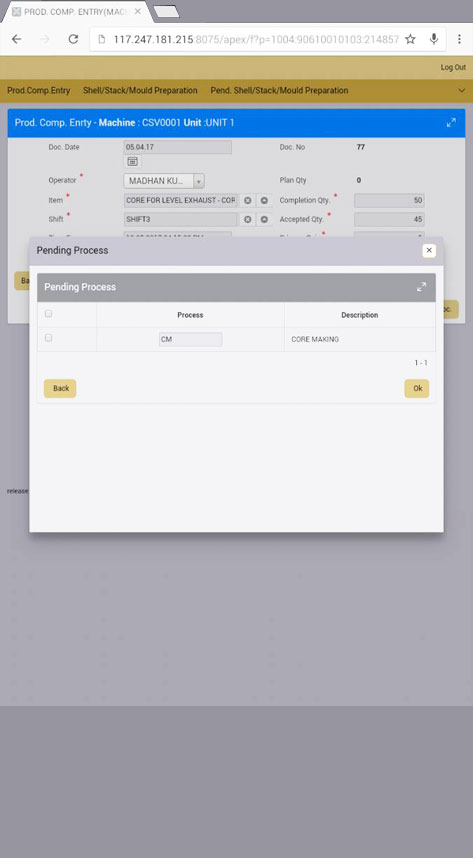

03

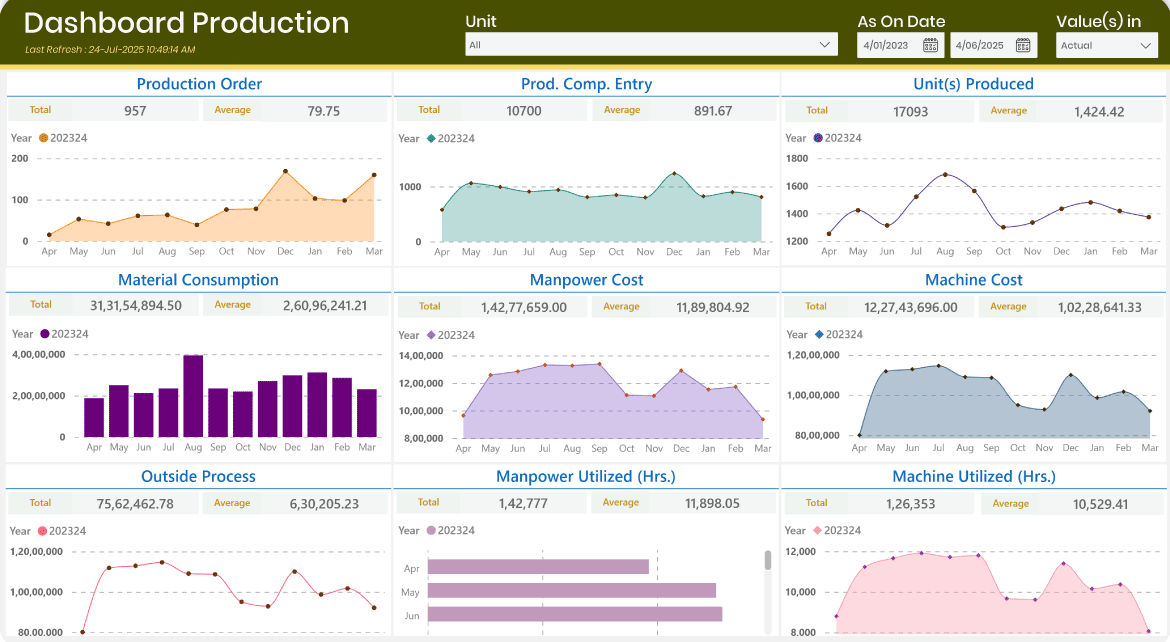

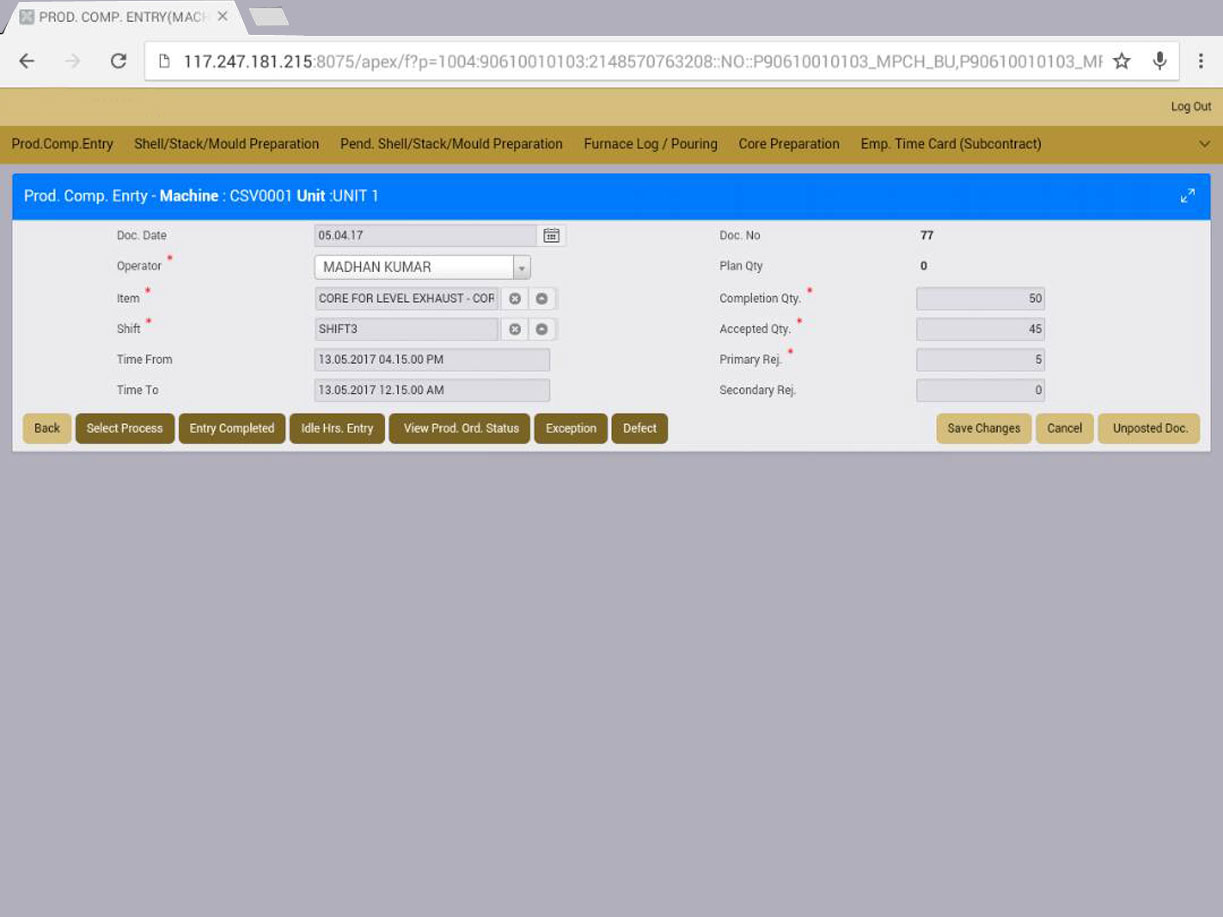

Shop Floor

Get to the very center of the Production process and gain access to the entire workflow, through on-screen / visual representation of the same, and acquire full knowledge of the work in order to address all its aspects.

01

Routing

Feel the power of possessing the entire picture of your business process and needs set to their time frames; learn what to do, discover the intricacies of your trade, and master the complexities of the procedures.

03

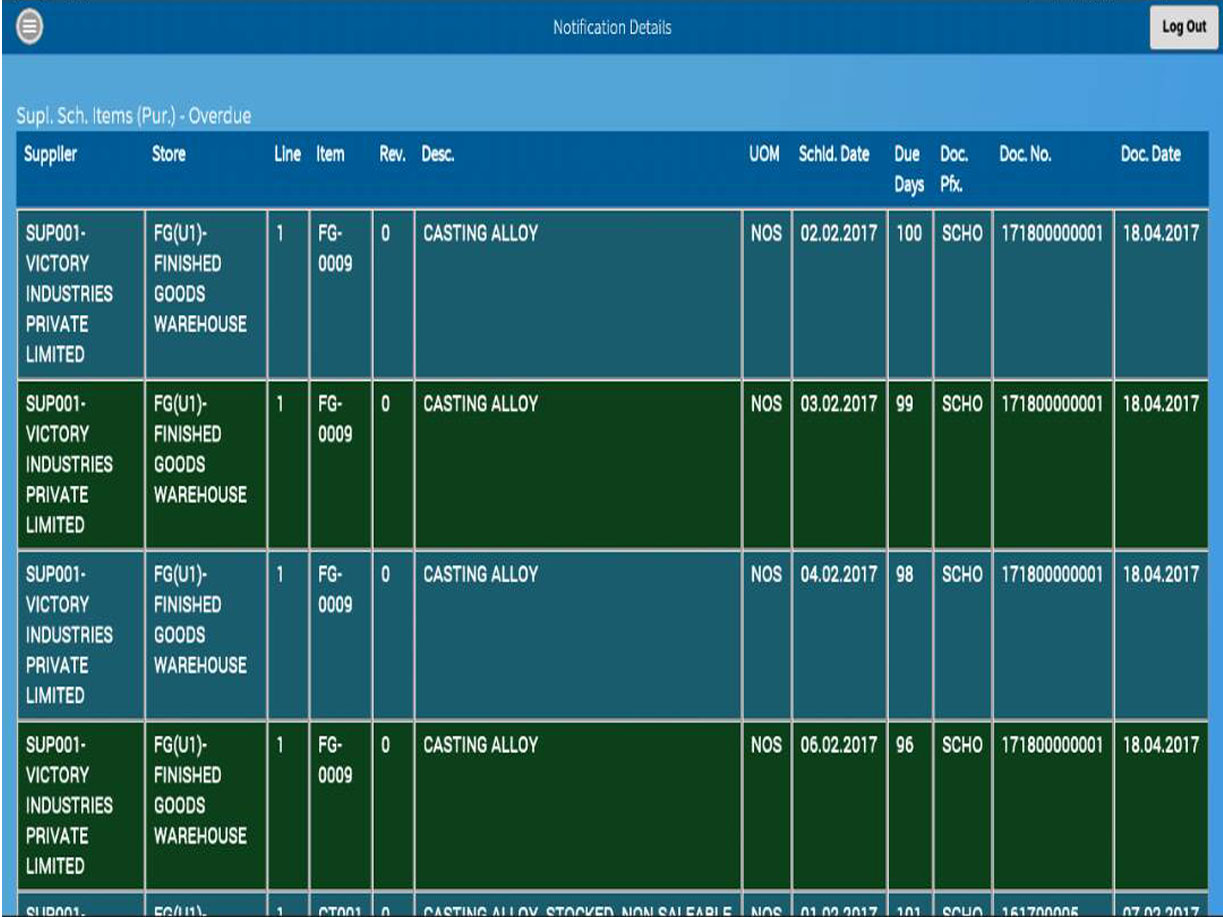

Demand Management

Be forecasted with the Do's and Dont's of your Production process, projected through an analysis of Inventory, workflow, and Customer demands, and meet all Production demands and never default one bit.

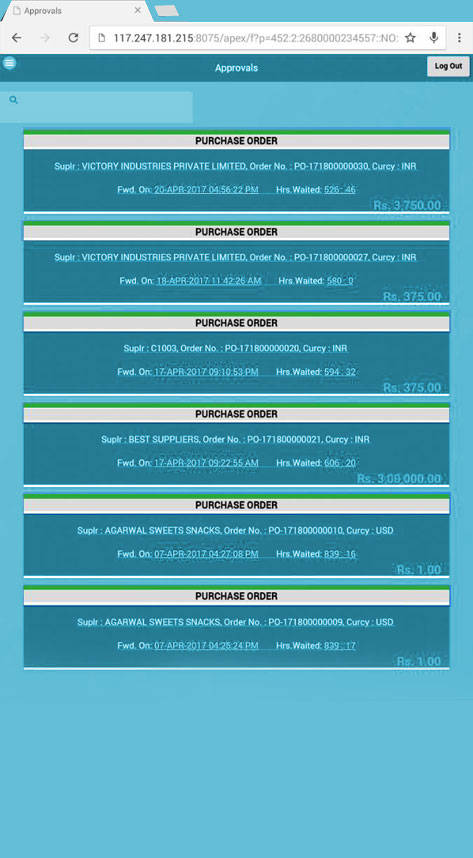

04

Master Production Schedule

Equip yourself to know when to produce, and how much to produce, while being able to wisely assign supplies, workforce and equipment for manufacturing; and confidently promise assured delivery dates.

06

Manufacturing Resource Planning (MRP II)

Perfectly determine the resources required for your Production procedure, through RCCP and CRP tools built into the facility, and exactly negotiate the best possible adjustments to achieve best Production results.

08

Manufacturing Schedule

Cleverly allocate plant and machinery, efficiently manage manpower and processes, and prudently procure and supply to optimize Production; and prioritize wisely to deliver total customer satisfaction.

Overview

Case Studies

Engineering, Procurement & Construction

An EPC company adopted Roadmap ERP to unify project planning, procurement, and resource management. The solution enabled accurate cost control, milestone tracking, and seamless collaboration across multiple sites—resulting in on-time project delivery and higher profitability.

Read moreFMCG Industries/Manufacturers

A Fast-Moving Consumer Goods Manufacturer leveraged Roadmap ERP to integrate production, warehousing, and distribution. By automating demand forecasting and batch tracking, stock outs were reduced, supply chain efficiency improved, and customer satisfaction increased.

Read more